Passive Aerosol DryerTM PAD-120

120 nm Clean Drying Process

50mm to 300mm Wafers & Larger Substrates

|

|

Liquid Diffusion Technology

ChemAcoustic's LIQUID DIFFUSION TECHNOLOGY (LDT) provides enhanced drying performance for a variety of substrates and material sufaces. This proprietary drying process and its subsystems control the creation of an ultra-pure IPA aerosol layer that moves across a motionless substrate to diffusively remove water, without leaving watermarks.

The VENTURI AEROSOL MAKER and its subsystem very efficiently creates the ultra-pure IPA aerosol layer with the robust process flexibility necessary to dry high aspect ratio / deep trench topography, half-pitch wafer spacing, and a wide variety of other applications. This subsystem uses no energy to passively create a unique range of IPA aerosols that other aerosol dryers simply cannot create. Furthermore, using an IPA aerosol in itself eliminates the safety hazard of IPA vapor dryers.

The ALWAYS CLEAN subsystem monitors the filtration and level of IPA to ensure that the IPA delivery path is always wet and the filter pressure is nominal. This eliminates the inconsistent performance of other aerosol dryers using a sonic head that dries out every cycle and then "self cleans" into the process bath.

The EZ-FRONT FILL subsystem is a combination of a front panel fill and IPA reservoir. This system enables non-intrusive, quick and easy IPA fills without removing panels or replacing storage bottles.

ChemAcoustic's PASSIVE AEROSOL DRYERS use all of the aforementioned proprietary subsystems to provide an efficient and clean drying system that is safe and environmentally-friendly.

|

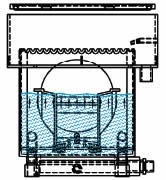

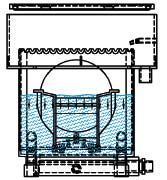

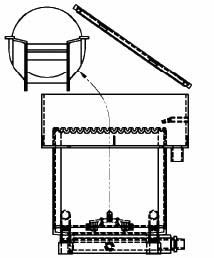

Step 1 Wafers loaded into DIW filled or unfilled Ultra-Clean, N2 Purged Chamber. |

|

Step 2 DIW Rinse for Time or Resistivity. |

|

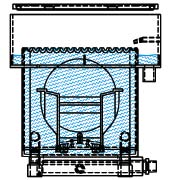

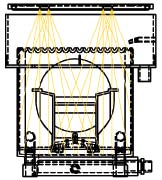

Step 3 VENTURI AEROSOL MAKER creates IPA Aerosol Layer on DIW Surface. |

|

Step 4 Control Drain of DIW/IPA Layer from Chamber Creating LDT Drying. |

|

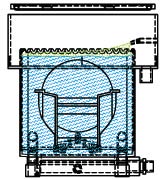

Step 5 Temperature & Flow Controlled N2 Assures Complete Drying. |

|

Step 6 Clean, Dry Wafers Unloaded and Ready for Next Process Step. |

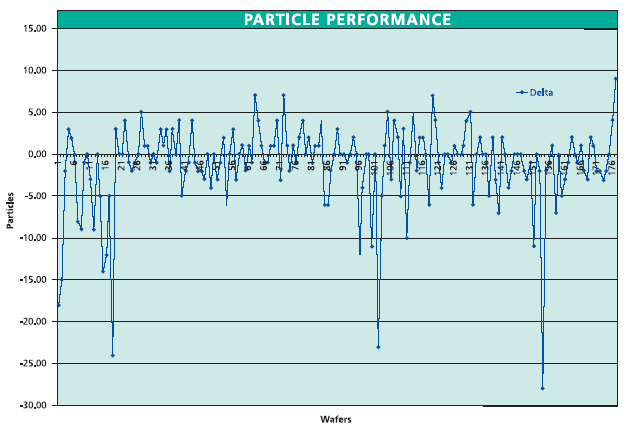

The Passive Aerosol Dryer (PAD-120) dries with particle neutral performance or better at 120 nm that is watermark free, regardless of wafer load size. These particle performance results were obtained and tested for particle performance at a customer's site while running actual application processes. A ChemAcoustic stand-alone dryer was used for these tests. OEM integrated dryers show even lower particle adders as a result of robotic handling.

Contact us at:

sales@chemacoustic.com