Passive Aerosol DryerTM PAD-200

200 nm Clean Drying Process

For Fragile Substrates

The Spin Rinse Dryer Replacement

|

|

Liquid Diffusion Technology

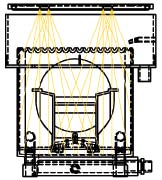

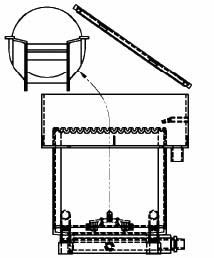

ChemAcoustic's LIQUID DIFFUSION TECHNOLOGY (LDT) provides enhanced drying performance for a variety of substrates and material sufaces. This proprietary drying process and its subsystems control the creation of an ultra-pure IPA aerosol layer that moves across a motionless substrate to diffusively remove water, without leaving watermarks.

The VENTURI AEROSOL MAKER and its subsystem very efficiently creates the ultra-pure IPA aerosol layer with a robust process flexibility. This subsystem uses no energy to passively create a unique range of IPA aerosols that other aerosol dryers simply cannot create. Furthermore, using an IPA aerosol in itself eliminates the safety hazard of IPA vapor dryers.

The PAD-200 delivers value-engineered performance. Designed as a less expensive alternative to the PAD-120 for drying fragile substrates where particle performance is not as demanding.

The PAD-200 is competitively priced to SRDs and delivers comparable particle performance. The PAD-200 is superior to SRDs in the prevention of substrate damage, significantly greater uptime, and by comparison, virtually eliminates maintenance. The PAD-200 never needs rebuilding, so why repeatedly rebuild your SRD when you can replace it with the PAD-200 and dramatically lower your COO?

|

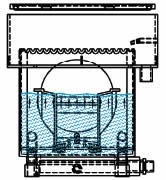

Step 1 Wafers loaded into DIW filled or unfilled Ultra-Clean, N2 Purged Chamber. |

|

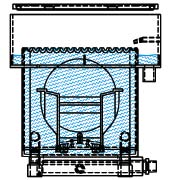

Step 2 DIW Rinse for Time or Resistivity. |

|

Step 3 VENTURI AEROSOL MAKER creates IPA Aerosol Layer on DIW Surface. |

|

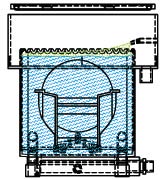

Step 4 Control Drain of DIW/IPA Layer from Chamber Creating LDT Drying. |

|

Step 5 Temperature & Flow Controlled N2 Assures Complete Drying. |

|

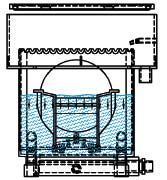

Step 6 Clean, Dry Wafers Unloaded and Ready for Next Process Step. |

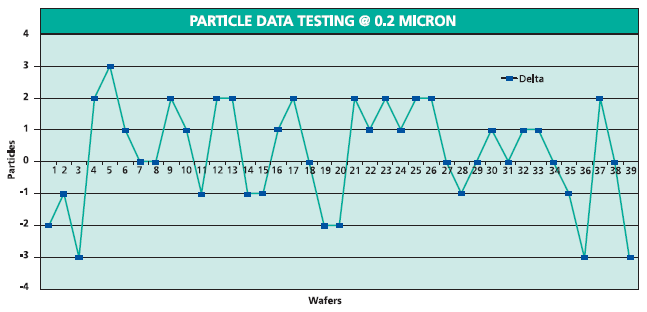

The Passive Aerosol Dryer (PAD-200) dries with particle neutral performance or better at 200 nm that is watermark free, regardless of wafer load size. These particle performance results were obtained and tested for particle performance at a customer's site while running actual application processes.

Contact us at:

sales@chemacoustic.com